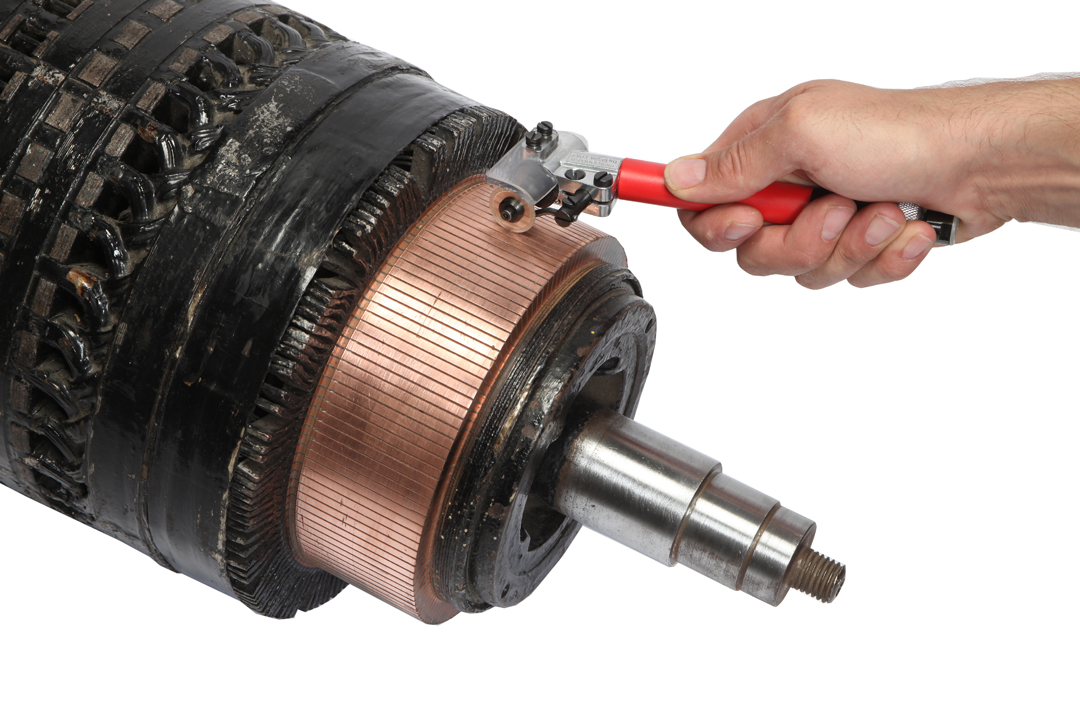

Again, the specific value is based on the motor design (wires per loop, number of turns per coil, and wire gauge). This will check every coil in the motor armature. The second check is the “Bar to Bar Resistance” test (pictured on right). A huge spike in resistance could indicate that a wire is burned through or broken, interrupting the circuit. A drop in resistance could indicate a short between wires in the coil. If the resistance drastically varies, there could be a problem with the Though you probably will not know the armature’s intended resistance value, each measurement should read about the same. For example, a 90 V dc motor will have smaller conductors and more turns per coil to raise resistance, whereas, a 12 V dc motor will have larger conductors and less turns per coil to lower resistance. It is also dependent upon the operating voltage for which the motor is designed. The resistance you will measure is dependent upon the number of turns in each coil and the gauge of wire used. Figure 3 depicts a 32 bar commutator, so this check must be done between each of the 16 pairs. Rotate the armature and check the resistance between every pair of bars on the commutator. Set the meter to measure resistance (Ohms) and then measure the resistance from two commutator bars 180° across from each other.

ELECTRIC MOTOR WINDING TOOLS SERIES

A volt/ohm meter can be used to check the resistance of the series windings connected between the two commutator bars of each coil.

The first check to see if your armature windings are shorted is the “180° Resistance” test. Depending upon brush size, this may allow access to the commutator without removing the armature from the motor. However, if the motor design has external brush holders, you can unscrew the brush caps and remove the brushes. To check the condition of the armature windings, the armature will probably have to be removed from the motor. If windings are shorted together, the electro-magnetic fields cannot be created for that coil, causing the motor to run erratically or fail all together. If a motor is driven too hard for its environment and temperatures are allowed to rise beyond the thermal limits of the insulation, it is possible for the insulation on the wires to break down and short together, or short to the armature stack. These magnetic forces work to attract each other, inducing a torque on the armature shaft, causing it to turn.

This EM field inter-acts with the magnetic fields of the permanent magnets in the motor (in the case of a permanent magnet motor) or with the electro-magnetic field created by the stator (in the case of a universal motor). When energized, an electro-magnetic field is generated in the motor armature. The turns in every coil wrap around the iron stack to create an electro-magnet. Each wire is insulated with an enamel coating, isolating it from every other wire in the loop, and only terminates at a commutator bar. The wire can vary in gauge as is required for the design of the motor. Loops are either single or parallel conductors (wires), and can circle any number of times around the stack teeth (called turns in a coil). The winding continues to loop all the way around the armature in the same manner. Basic Armature DesignĪn armature (pictured on right) has a continuous series of windings from each bar on the commutator, which loop around the iron stack teeth and connect to the next bar on the commutator. But first we must understand some basics of armature design. If you have access to a volt/ohm meter, there are three quick checks you can do that will tell you if a motor armature is functioning properly.

Occasionally we get this question from our customers, “How can I do a quick check on my armature to see if it is ok?”

ELECTRIC MOTOR WINDING TOOLS HOW TO

Watch the video: how to check a motor armature.

0 kommentar(er)

0 kommentar(er)